Diamonds are a Floor’s Best Friend – Armstrong’s Diamond 10® Technology Changes the Face of Commercial Flooring

Armstrong Flooring has always been a pioneer of possibilities in floor covering, and their Diamond 10® Technology is another game changer. Originally launched in 2015 as a coating on Armstrong’s luxury vinyl tile collections, Diamond 10 is now available on a wide range of surfaces: luxury vinyl tile, sheet flooring and, most recently and notably, VCT.

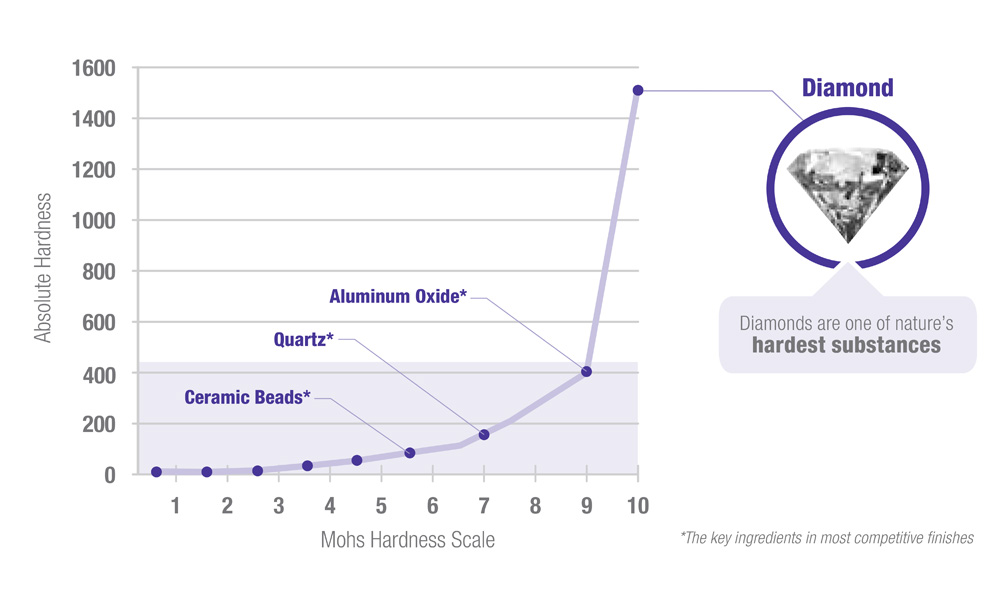

There is a growing need for the combination of high durability and low maintenance across the commercial flooring spectrum, including healthcare flooring, school flooring and government flooring. Diamond 10® Technology utilizes the resilient properties of cultured diamonds to create a floor finish that outperforms the rest. On the Mohs scale of mineral hardness (which characterizes the scratch resistance of various materials), Diamond 10® had a perfect score.

Benefits of Diamond 10® Technology Flooring:

- Exceptional ease of maintenance

- Unmatched durability

- Washable surface that cleans and dries quickly using common maintenance supplies

- No polish required (though polish may be added for higher sheen)

- Withstands heavy traffic

- Scratch, stain and scuff resistant

- Large selection of surfaces, designs and colors

Diamond 10® Technology and VCT

Joining LVT and polished concrete in the low maintenance category, this is the only VCT to offer superior scratch, stain and scuff resistance without polish, reducing the total cost of ownership over the life of the floor.

“Armstrong Flooring’s VCT, now with our exclusive Diamond 10® Technology coating, delivers superior scratch, stain and scuff resistance, saving on average over 40% in maintenance costs compared to polished VCT,” said Brian Saker, Director, Commercial Product Management. “While savings depend on use and recommended maintenance procedures, for large retail chain customers this can result in millions of dollars in savings over the life of the floor and will completely change the value proposition in their flooring selection.”

With dirt, scratch and stain resistant qualities, VCT with Diamond 10® Technology is unlike traditional VCT in that it offers the option to reduce or eliminate initial polish and recoating maintenance and eliminates restorative stripping in all applications; fewer coats of polish means less downtime and a quick return to operational space. Savings are realized in polish costs, as well as labor costs related to maintenance practices. In addition, with standard VCT, where a higher sheen is desired, it can take up to eight coats of polish to achieve the desired gloss level; with VCT with Diamond 10® Technology, the same gloss level can be achieved with as little as three coats of polish.

Made in USA with global and domestic content, VCT offers the lowest carbon footprint of all Armstrong Flooring resilient products and is recyclable through Armstrong’s On&On™ Recycling Program. VCT offers many benefits over polished concrete, with customers who might previously have chosen polished concrete indicating they love the look, comfort, durability, price and maintenance of this game-changing, value-priced flooring product. The durable construction of VCT ensures lasting beauty in high-traffic areas, while flowing linear patterns, organic looks, and densely patterned earth tones effectively mask scuffs and soil in busy commercial spaces.

Continental Flooring offers all Armstrong’s Diamond 10® Technology products. We supply materials only or complete installation services. Please add our website to your list of favorites and check back periodically as we continue to grow our product lines and offerings. To learn more, please contact a sales representative or complete our Quote Request Form. Call 800-825-1221

One call does it all!