Preparation is Key – The Importance of Understanding Subfloors

When purchasing flooring for any project, the subfloor should always be a part of the conversation. The type of existing subfloor, or the subfloor being put in, can influence which product is most effective for the surface and the space. The subfloor can make or break a successful flooring installation and it’s important that installers and buyers understand what will work best for the product being used. Whether it’s carpet, sheet vinyl, LVT, or ceramic, preparing the subfloor correctly is the key to the product performance and durability.

What is a subfloor?

In construction, there is a joist system that runs between beams or load-bearing walls. This joist system holds up the entire floor. In some modern construction, long engineered joists use I-beams. With slab construction, the concrete slab is the actual subfloor. A good flooring installer will understand the joist system and how it will affect the subfloor and the installation itself. A subfloor can be wood, concrete, plywood, stone, or metal. Based on the type of subfloor in the building, certain preparation will need to be done so the flooring material is adhered, floated, or stretched correctly to ensure the product is not compromised.

What is underlayment?

From a terminology perspective is imperative to understand the difference between subfloor and underlayment. The term “subfloor” is sometimes confused with “underlayment.” Underlayment is the material immediately under the floor covering itself like foam padding, cement board, troweled mortar, or thin plywood. (Note: flooring moisture barriers are placed beneath the floor’s underlayment. The moisture barrier can be installed separately or underlayment with a moisture barrier built-in is available.) The underlayment is not a structural element, its job is to smooth out an already prepared subfloor.

Preparing a Subfloor

The success of any installation is how the flooring material adheres to the surface where it is being put down. A well-prepared subfloor needs to be:

- Clean and dry

- Free of oil, grease, dust, grit, and any chemical contaminants

- Free of old adhesives or loose or broken patching agents

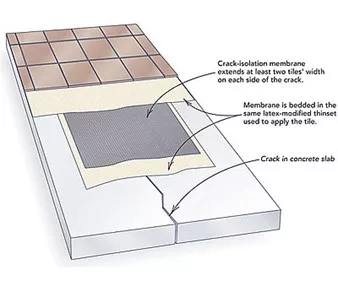

- Free of cracks wide enough to impact the flooring material

- Sturdy

- Flat

- Level

Concrete Subfloors

In commercial settings, most subfloors are concrete. Concrete is constantly in flux. Because of its makeup, concrete never completely dries and is always subject to some degree of moisture. Concrete is made up of chemicals and minerals that can sometimes prevent flooring adhesives from working effectively. Because concrete is porous, contaminants like oil, grease, or any oil-based compounds on the surface may cause the adhesion to fail. With so many factors to consider with concrete subfloor, a knowledgeable installation crew will make the difference.

There is a lot to know about the dos and don’ts of subfloor preparation. Whether the installation consists of hard or soft surface material, it will take expertise and skill to ensure the best outcomes and the most beautiful and long-lasting flooring project.

Please feel free to contact us for product advice, free samples, assistance in specifications, or to place an order. We welcome contract purchases, formal bids, RFQs or Open Market requirements. One call will do it all!

Contact Us Today!

Call Toll Free 800-825-1221 | Request a Quote

Email: info@continentalflooring.com

Our Segments

- Federal, State, County, and Municipalities

- Healthcare

- Schools, Colleges, and Universities

- Public Housing Authority (PHA)

Continental Flooring has been servicing government agencies since 1979 and continues to be a top flooring and ceiling provider in the public sector.